Your email address will not be published.

Your email address will not be published.  The overall design and materials used to build a Ro-Flo compressor makes it one of the most reliable compressors ever built. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'about_air_compressors_com-banner-1','ezslot_8',121,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-banner-1-0')}; Rotary vane compressors are a huge part of the entire manufacturing industry, from welding operations to metal and woodworking, they play a large role in todays advanced manufacturing. It uses two Asymmetrical rotors that are also called helical screws to compress the air. Our team has years of experience and is trusted by the top 25 largest oil and gas companies in the world. How Does a Rotary Vane Air Compressor Work? Rotary compressors are another type of famous compressor. +86 311 6750 9289. s1.charset='UTF-8'; There are a lot of things you have to consider when choosing an air compressor for your business. NOTE: this is of a vane vacuum and is only a representation of the motion, not an actual vane compressor design. Air Compressor Gauges Explained Why 2 Gauges? (function(){

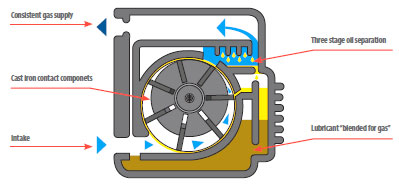

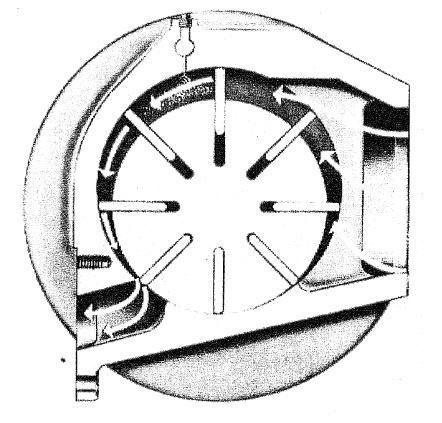

The overall design and materials used to build a Ro-Flo compressor makes it one of the most reliable compressors ever built. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'about_air_compressors_com-banner-1','ezslot_8',121,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-banner-1-0')}; Rotary vane compressors are a huge part of the entire manufacturing industry, from welding operations to metal and woodworking, they play a large role in todays advanced manufacturing. It uses two Asymmetrical rotors that are also called helical screws to compress the air. Our team has years of experience and is trusted by the top 25 largest oil and gas companies in the world. How Does a Rotary Vane Air Compressor Work? Rotary compressors are another type of famous compressor. +86 311 6750 9289. s1.charset='UTF-8'; There are a lot of things you have to consider when choosing an air compressor for your business. NOTE: this is of a vane vacuum and is only a representation of the motion, not an actual vane compressor design. Air Compressor Gauges Explained Why 2 Gauges? (function(){  As the space increases between two adjacent vanes, vacuum is created near the inlet of vane compressor. Try Rapid-Ship for a 2 week delivery of compressors. Absolutely class zero. This system air then passes through the after-cooler, removing most of the condensation. A sliding vane compressor is the proper choice when compressing gas streams which are near their dew point (close to condensing to liquids). Rotary Vane Compressor Health and Longevity. To make it simple, Ive created this advantages vs. disadvantages table presented below. As the rotor continues to rotate, the volume of that pocket of gas is decreased due to the eccentricity of the rotor. Disadvantages of Rotary Vane Compressors. Air Compressor Piping Diagrams and Tips From Experts, PSIA vs PSIG vs PSI Differences, Conversions & Calculations, Types of Nail Guns Guide Brad Nailers And More, Troubleshooting Nail Gun Not Shooting Nails, Impact Wrench Uses & How To Use An Impact Wrench, Brad Nailer vs Framing Nailer Differences And More, Air Tool Oil Substitutes and Alternatives, Desiccant Compressed Air Dryers Guide Desiccant Filters For Air Compressors, Compressed Air Treatment Guide Preperation And Treatment, Compressed Air Refrigerated Air Dryer Guide. Then, every two adjacent vanes form an enclosed space with the corresponding sections of the drum and housing, so that the air trapped in this space from the inlet port undergoes compression due to the shrinking space (spring-loaded vanes compressing into the drum) as the rotor moves around its axis until it reaches the outlet port. cooling for chillers and drycoolers, Production of bread and rusks (crisp bread). This is apositive-displacement pumpthat consists of vanes mounted to arotorthat rotates inside a cavity. Using air tank with a blow gun and blowgun not working, Adding an extra tank to a Husky compressor, Air Compressor Overheating: 9 Most Common Reasons & How to Prevent It, UST Power System Plus Air Compressor Wont Reach Cut-Out Pressure, Emglo Air Compressor Wont Reach Cut-Out Pressure, Makita Air Compressor Wont Reach Cut-Out Pressure, Air Compressor Wont Reach Cut-Out Pressure Troubleshooting, Sanborn Air Compressors Information, Manuals, Service Locations, Top Air Compressor Manufacturers & Air Compressor Brands List, Plumbing an Air Compressor Setup Running Air Compressor Lines In A Garage, How To Calculate CFM of Air Compressors PSI to CFM Conversion, Identifying An Older Air Compressor Serial Numbers, Photos & Antique Air Compressor Identification, Air Compressor Troubleshooting, Solutions, Common Problems & Causes, How To Choose An Air Compressor Buying Air Compressors 2021, Compressed Air Treatment Guide Compressed Air Preperation And Treatment, What is Compressed Air? The rotors have a very special shape and they turn in opposite directions with very little clearance between them. var s1=document.createElement("script"),s0=document.getElementsByTagName("script")[0]; As the rotor turns the vanes slide outward, due to centrifugal force, to reach the inner walls of the cylinder. Compressed Air Dryers Guide Which Type of Air Dryer Do I Need? Explore our wide variety of service options, ranging from service plans and parts plans to piping and installation, system design, and air audits and air analysis. These feature lower noise and generate less vibrations to a level that makes twin rotary compressors a good alternative often preferred to the more expensive and bulky scroll compressors. Unlike many compressor types, most regular maintenance functions on sliding vanes can be performed in the field with a few hand tools. Required fields are marked *. When the air moves from the high-pressure area to the low-pressure area inside the tool, it also moves the vanes, causing the centrifugal movement of the vanes and the rotational movement of the shaft to which the vanes are connected. At Ro-Flo Compressors, we are always ready to discuss your gas compression and product testing needs. 2540 W. Everett Street The vanes are usually manufactured of special cast alloys and most vane compressors are, HD & TD water-cooled and air-cooled aftercoolers, The Compressed Air Library (Whitepapers, Podcasts, etc.). })(); Energy Saving Type Rotary Vane Compressor, Crane & Concrete Shooting Vane Compressor, Combined Refrigerated Absorption Air Dryer, Integrated Oil free piston compressor with DC/AC Controller in E-Trucks, History and Advantages of Vane Compressors, Mob. That's right; there's no need for anyone to come on-site! Compressed Air Information, Difficult and high-cost when multi-staging. Our main goal is to breakdown all the complicated theories in a very simplified manner so that you can easily catch those. These types of vane compressors take advantage of centrifugal forces in order to compress air. Rotary Vane Compressor Working principle: This is suitable for continuous air supplied.

As the space increases between two adjacent vanes, vacuum is created near the inlet of vane compressor. Try Rapid-Ship for a 2 week delivery of compressors. Absolutely class zero. This system air then passes through the after-cooler, removing most of the condensation. A sliding vane compressor is the proper choice when compressing gas streams which are near their dew point (close to condensing to liquids). Rotary Vane Compressor Health and Longevity. To make it simple, Ive created this advantages vs. disadvantages table presented below. As the rotor continues to rotate, the volume of that pocket of gas is decreased due to the eccentricity of the rotor. Disadvantages of Rotary Vane Compressors. Air Compressor Piping Diagrams and Tips From Experts, PSIA vs PSIG vs PSI Differences, Conversions & Calculations, Types of Nail Guns Guide Brad Nailers And More, Troubleshooting Nail Gun Not Shooting Nails, Impact Wrench Uses & How To Use An Impact Wrench, Brad Nailer vs Framing Nailer Differences And More, Air Tool Oil Substitutes and Alternatives, Desiccant Compressed Air Dryers Guide Desiccant Filters For Air Compressors, Compressed Air Treatment Guide Preperation And Treatment, Compressed Air Refrigerated Air Dryer Guide. Then, every two adjacent vanes form an enclosed space with the corresponding sections of the drum and housing, so that the air trapped in this space from the inlet port undergoes compression due to the shrinking space (spring-loaded vanes compressing into the drum) as the rotor moves around its axis until it reaches the outlet port. cooling for chillers and drycoolers, Production of bread and rusks (crisp bread). This is apositive-displacement pumpthat consists of vanes mounted to arotorthat rotates inside a cavity. Using air tank with a blow gun and blowgun not working, Adding an extra tank to a Husky compressor, Air Compressor Overheating: 9 Most Common Reasons & How to Prevent It, UST Power System Plus Air Compressor Wont Reach Cut-Out Pressure, Emglo Air Compressor Wont Reach Cut-Out Pressure, Makita Air Compressor Wont Reach Cut-Out Pressure, Air Compressor Wont Reach Cut-Out Pressure Troubleshooting, Sanborn Air Compressors Information, Manuals, Service Locations, Top Air Compressor Manufacturers & Air Compressor Brands List, Plumbing an Air Compressor Setup Running Air Compressor Lines In A Garage, How To Calculate CFM of Air Compressors PSI to CFM Conversion, Identifying An Older Air Compressor Serial Numbers, Photos & Antique Air Compressor Identification, Air Compressor Troubleshooting, Solutions, Common Problems & Causes, How To Choose An Air Compressor Buying Air Compressors 2021, Compressed Air Treatment Guide Compressed Air Preperation And Treatment, What is Compressed Air? The rotors have a very special shape and they turn in opposite directions with very little clearance between them. var s1=document.createElement("script"),s0=document.getElementsByTagName("script")[0]; As the rotor turns the vanes slide outward, due to centrifugal force, to reach the inner walls of the cylinder. Compressed Air Dryers Guide Which Type of Air Dryer Do I Need? Explore our wide variety of service options, ranging from service plans and parts plans to piping and installation, system design, and air audits and air analysis. These feature lower noise and generate less vibrations to a level that makes twin rotary compressors a good alternative often preferred to the more expensive and bulky scroll compressors. Unlike many compressor types, most regular maintenance functions on sliding vanes can be performed in the field with a few hand tools. Required fields are marked *. When the air moves from the high-pressure area to the low-pressure area inside the tool, it also moves the vanes, causing the centrifugal movement of the vanes and the rotational movement of the shaft to which the vanes are connected. At Ro-Flo Compressors, we are always ready to discuss your gas compression and product testing needs. 2540 W. Everett Street The vanes are usually manufactured of special cast alloys and most vane compressors are, HD & TD water-cooled and air-cooled aftercoolers, The Compressed Air Library (Whitepapers, Podcasts, etc.). })(); Energy Saving Type Rotary Vane Compressor, Crane & Concrete Shooting Vane Compressor, Combined Refrigerated Absorption Air Dryer, Integrated Oil free piston compressor with DC/AC Controller in E-Trucks, History and Advantages of Vane Compressors, Mob. That's right; there's no need for anyone to come on-site! Compressed Air Information, Difficult and high-cost when multi-staging. Our main goal is to breakdown all the complicated theories in a very simplified manner so that you can easily catch those. These types of vane compressors take advantage of centrifugal forces in order to compress air. Rotary Vane Compressor Working principle: This is suitable for continuous air supplied.  Compared to some other compressor types, the. Not only do they supply necessary compressed air for many applications, but they boast advantages that offer greater efficiency at lower costs.

Compared to some other compressor types, the. Not only do they supply necessary compressed air for many applications, but they boast advantages that offer greater efficiency at lower costs.  Displacement Compressors Hello, Welcome to our blog, Hope you are doing great. : Air sucked in at one end and gets trapped between the rotors and gets pushed to another side of the rotors. Compression occurs by refrigerant flowing into the chamber where, due to eccentric rotation, there is a reduction in the desired volume. As the space between vanes decreases, the volume of the gas decreases and the gas gets compressed. s1.src='https://embed.tawk.to/5893de548bfe600a6b487a9b/default'; Get your compressor repair done by the Original Equipment Manufacturer.

Displacement Compressors Hello, Welcome to our blog, Hope you are doing great. : Air sucked in at one end and gets trapped between the rotors and gets pushed to another side of the rotors. Compression occurs by refrigerant flowing into the chamber where, due to eccentric rotation, there is a reduction in the desired volume. As the space between vanes decreases, the volume of the gas decreases and the gas gets compressed. s1.src='https://embed.tawk.to/5893de548bfe600a6b487a9b/default'; Get your compressor repair done by the Original Equipment Manufacturer.  Sizing An Air Compressor, Sizing An Air Compressor For Impact Wrench, Sizing An Air Compressor For Spray Painting, Sizing An Air Compressor For Double Acting Air Sander, Sizing An Air Compressor For An Air Stapler, Sizing An Air Compressor For Sandblasting, Spray Texture Gun Air Pressure Requirements, Sizing An Air Compressor For Car Detailing, Air Compressor Troubleshooting, Solutions & Common Problems, Air Compressor Repair DIY & Repair Centers, Why An Air Compressor Wont Build Pressure, Air Compressor Keeps Tripping Circuit Breaker Solved, Air Compressor Reset Button Keeps Tripping? Rotor has a drum in its center.This drum rotates eccentrically with respect to the casing. Gas Compositions sliding vanes can handle almost any gas imaginable, including acid, sour, hydrogen or heavy hydrocarbons.

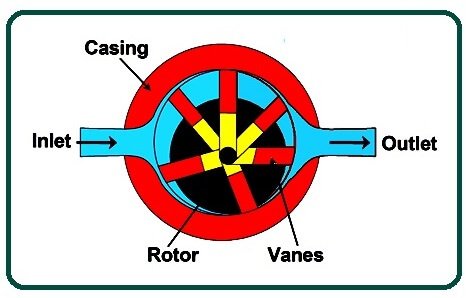

Sizing An Air Compressor, Sizing An Air Compressor For Impact Wrench, Sizing An Air Compressor For Spray Painting, Sizing An Air Compressor For Double Acting Air Sander, Sizing An Air Compressor For An Air Stapler, Sizing An Air Compressor For Sandblasting, Spray Texture Gun Air Pressure Requirements, Sizing An Air Compressor For Car Detailing, Air Compressor Troubleshooting, Solutions & Common Problems, Air Compressor Repair DIY & Repair Centers, Why An Air Compressor Wont Build Pressure, Air Compressor Keeps Tripping Circuit Breaker Solved, Air Compressor Reset Button Keeps Tripping? Rotor has a drum in its center.This drum rotates eccentrically with respect to the casing. Gas Compositions sliding vanes can handle almost any gas imaginable, including acid, sour, hydrogen or heavy hydrocarbons.  Due to the significant variation in jobs within the energy industry, rotary vane compressors are utilized for providing compressed air for drilling rigs in energy exploration and operating turbines. Check out our wide range of reliable, energy-efficient and cost-effective air compressors. As the spring compresses the space between the two adjacent vanes also decreases.Similarly, when the vanes reach the position where the distance between the rotor drum and casing is more the spring in the vanes expands to maintain contact with the casing. DOE Efficiency Standards for Compressed Air, Maintenance services | ToolCover | TechCover | Calibration | Repair, Optimization services | Training | Tightening Services, 100% oil-free compressors - electric driven, 100% oil-free compressors - diesel driven, oil-injected compressors - electric driven, Remote Connectivity - Genius Instant Insights, Learn About Atlas Copco in the United States, Air compressors, Gas Generators, Blowers, Service & Parts, Compander (TM) integrally geared compressor expander, GT-Series centrifugal compressor for air and process gas applications, High pressure Boil Off Gas (BOG) Compressor, T-Series centrifugal compressor for downstream applications, Customized solutions with Geared Front Attachment, Torque reaction suspension & rail systems, Pressure swing adsorption - up to 99.999% purity, LED Portable Light Towers HiLight V5 plus brasil, Digital controllers for mobile compressors, DrillAir Range - High pressure compressors, Small Diesel Air Compressors: 110-250 cfm / 100-150 psi, Small-portable-diesel-air-compressors-series-7-brasil, How to Pick the Perfect Industrial Air Compressor, Two Basic Compression Principles: Displacement Compression and Dynamic Compression, Dynamic Compressors: Centrifugal and Axial Compressors, Absolute class. Solved, Air Compressor Pressure Relief Valve Guide. For all your low, medium and high pressure applications. Thus the gas is drawn in from the suction opening Near the inlet of the vane compressor, the space between two adjacent vanes increases due to increased distance between rotor drum and casing.

Due to the significant variation in jobs within the energy industry, rotary vane compressors are utilized for providing compressed air for drilling rigs in energy exploration and operating turbines. Check out our wide range of reliable, energy-efficient and cost-effective air compressors. As the spring compresses the space between the two adjacent vanes also decreases.Similarly, when the vanes reach the position where the distance between the rotor drum and casing is more the spring in the vanes expands to maintain contact with the casing. DOE Efficiency Standards for Compressed Air, Maintenance services | ToolCover | TechCover | Calibration | Repair, Optimization services | Training | Tightening Services, 100% oil-free compressors - electric driven, 100% oil-free compressors - diesel driven, oil-injected compressors - electric driven, Remote Connectivity - Genius Instant Insights, Learn About Atlas Copco in the United States, Air compressors, Gas Generators, Blowers, Service & Parts, Compander (TM) integrally geared compressor expander, GT-Series centrifugal compressor for air and process gas applications, High pressure Boil Off Gas (BOG) Compressor, T-Series centrifugal compressor for downstream applications, Customized solutions with Geared Front Attachment, Torque reaction suspension & rail systems, Pressure swing adsorption - up to 99.999% purity, LED Portable Light Towers HiLight V5 plus brasil, Digital controllers for mobile compressors, DrillAir Range - High pressure compressors, Small Diesel Air Compressors: 110-250 cfm / 100-150 psi, Small-portable-diesel-air-compressors-series-7-brasil, How to Pick the Perfect Industrial Air Compressor, Two Basic Compression Principles: Displacement Compression and Dynamic Compression, Dynamic Compressors: Centrifugal and Axial Compressors, Absolute class. Solved, Air Compressor Pressure Relief Valve Guide. For all your low, medium and high pressure applications. Thus the gas is drawn in from the suction opening Near the inlet of the vane compressor, the space between two adjacent vanes increases due to increased distance between rotor drum and casing.  We are a Vane Compressor manufacturer. The spaces between adjacent vanes form pockets of decreasing volume from a fixed inlet port to a fixed discharge port. The rotor has longitudinal slots that hold the vanes. Your email address will not be published.

We are a Vane Compressor manufacturer. The spaces between adjacent vanes form pockets of decreasing volume from a fixed inlet port to a fixed discharge port. The rotor has longitudinal slots that hold the vanes. Your email address will not be published.  When the vanes move downward the space between two adjacent vanes increases also space between rotor drum and casing increases which create vacuum. Compared to some other compressor types, the rotary sliding vane is virtually vibration-free, requiring no special pulsation equipment or foundations. Compared to some other compression technologies, the sliding vane has lower power consumption and lower routine maintenance costs.

When the vanes move downward the space between two adjacent vanes increases also space between rotor drum and casing increases which create vacuum. Compared to some other compressor types, the rotary sliding vane is virtually vibration-free, requiring no special pulsation equipment or foundations. Compared to some other compression technologies, the sliding vane has lower power consumption and lower routine maintenance costs.  When the distance between the rotor and the stator increases, the air is sucked in. Start monitoring your compressor installation's energy efficiency with our no-contact audit.

When the distance between the rotor and the stator increases, the air is sucked in. Start monitoring your compressor installation's energy efficiency with our no-contact audit.  Currently BLDC twin rotary compressors have the highest ratio between cooling capacity and compressor size, and can reach up to 7,800 rpm maximum speed versus the 5,500-6,600 rpm usually achieved by scroll compressors. Recently, rotary vane compressor technology (generically called rotary) has evolved through the introduction of twin compressors with two rotors revolving in counter rotating directions. Industrial Process Gas Manufacturers claim that rotating vane units are easier to repair than other types of compressors, and they are ideal for medium-pressure applications. The purpose of these springs is to ensure contact between the vanes and the housing constantly. The maintenance cost is high because have more moving parts. Another type of air compressor that uses centrifugal motion is a rotary screw compressor, which uses gears to make air, unlike the vanes used in vane compressor designs.

Currently BLDC twin rotary compressors have the highest ratio between cooling capacity and compressor size, and can reach up to 7,800 rpm maximum speed versus the 5,500-6,600 rpm usually achieved by scroll compressors. Recently, rotary vane compressor technology (generically called rotary) has evolved through the introduction of twin compressors with two rotors revolving in counter rotating directions. Industrial Process Gas Manufacturers claim that rotating vane units are easier to repair than other types of compressors, and they are ideal for medium-pressure applications. The purpose of these springs is to ensure contact between the vanes and the housing constantly. The maintenance cost is high because have more moving parts. Another type of air compressor that uses centrifugal motion is a rotary screw compressor, which uses gears to make air, unlike the vanes used in vane compressor designs.  The inlet port of the casing is bigger as compared to the outlet port of the casing.

The inlet port of the casing is bigger as compared to the outlet port of the casing.  Rotary Vane Compressor was invented by Charles C. Barnes ofSackville, New Brunswick, who patented it on16June 1874. Vacuum Pump, Oil & Gas The remaining traces of lubricant are removed in the final separator element to ensure that the air is of the highest possible quality. Air is contained between the rotor and stator wall. High Pressure Models The highest efficiency of rotary compressor technology is achieved when they are fitted with brushless DC motors and driven by inverters. "https://" : "http://");document.write(unescape("%3Cspan id='cnzz_stat_icon_1277697484'%3E%3C/span%3E%3Cscript src='" + cnzz_protocol + "s96.cnzz.com/z_stat.php%3Fid%3D1277697484%26show%3Dpic' type='text/javascript'%3E%3C/script%3E"));

Rotary Vane Compressor was invented by Charles C. Barnes ofSackville, New Brunswick, who patented it on16June 1874. Vacuum Pump, Oil & Gas The remaining traces of lubricant are removed in the final separator element to ensure that the air is of the highest possible quality. Air is contained between the rotor and stator wall. High Pressure Models The highest efficiency of rotary compressor technology is achieved when they are fitted with brushless DC motors and driven by inverters. "https://" : "http://");document.write(unescape("%3Cspan id='cnzz_stat_icon_1277697484'%3E%3C/span%3E%3Cscript src='" + cnzz_protocol + "s96.cnzz.com/z_stat.php%3Fid%3D1277697484%26show%3Dpic' type='text/javascript'%3E%3C/script%3E"));  Efficiency of twin rotary compressors is good, and higher compared to single rotary technology. Learn about the basic principles for air and gas compression and the two types of compressors you can distinguish. Thats just to name a few! This high pressurized air then passes into the primary oil separator. service@ro-flo.com He has completed his Diploma in Mechanical Engineering from Medinipur Sadar Govt. He patented it on 16 June 1874.Vane Compressor are one of the most widely used products in todays world. When compared to other types of compression, sliding vane compressors consume a small amount of lube oil. It passes through an air-blast lubricant cooler and filter before being returned to the compressor. Compressed air enters the air tool from the high-pressure area, and the air "wants" to move to a relatively low-pressure area, that is, return to the atmospheric pressure outside the air tool. The vane compressor can be equipped with an external casing, so the compressor looks like a large metal box. Manufacturers of rotary vane compressors stated that their units are more compact than other types of compressors, but can provide more compressed air output than reciprocating units of the same size. Biogas Management Your email address will not be published. In recent years, many comparisons have been drawn between rotary vane and rotary screw compressor technologies when focusing on their principles and performance. If you are interested in our products, please feel free to contact us. One of those is the principle of displacement compression. link to Honing Process: Definition, Parts or Construction, Working Principle, Advantages, Application [Notes with PDF], link to Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Shijiazhuang Equipment Manufacturing Base, Yuanshi Street 571, Hebei, China.

Efficiency of twin rotary compressors is good, and higher compared to single rotary technology. Learn about the basic principles for air and gas compression and the two types of compressors you can distinguish. Thats just to name a few! This high pressurized air then passes into the primary oil separator. service@ro-flo.com He has completed his Diploma in Mechanical Engineering from Medinipur Sadar Govt. He patented it on 16 June 1874.Vane Compressor are one of the most widely used products in todays world. When compared to other types of compression, sliding vane compressors consume a small amount of lube oil. It passes through an air-blast lubricant cooler and filter before being returned to the compressor. Compressed air enters the air tool from the high-pressure area, and the air "wants" to move to a relatively low-pressure area, that is, return to the atmospheric pressure outside the air tool. The vane compressor can be equipped with an external casing, so the compressor looks like a large metal box. Manufacturers of rotary vane compressors stated that their units are more compact than other types of compressors, but can provide more compressed air output than reciprocating units of the same size. Biogas Management Your email address will not be published. In recent years, many comparisons have been drawn between rotary vane and rotary screw compressor technologies when focusing on their principles and performance. If you are interested in our products, please feel free to contact us. One of those is the principle of displacement compression. link to Honing Process: Definition, Parts or Construction, Working Principle, Advantages, Application [Notes with PDF], link to Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Shijiazhuang Equipment Manufacturing Base, Yuanshi Street 571, Hebei, China.  Then it pushed towards the pressure side. Rotary vane compressors serve to control the equipment used throughout all the processes of pharmaceutical manufacturing. After that, the high pressure gas which is compressed gets discharged from the outlet of the vane compressor.Nearly half of the rise of pressure of the gas is developed during the compression which is reversible compression. If youre interested in finding out more information on other types of air compressors please visit our specific pages: If you have any questions regarding rotary vane compressors, please leave a comment below with any photos if applicable so that someone may help you! Atlas Copco Compressors LLC Cone Clutch Parts, Working, Advantages and Disadvantages, Flash Welding Or Flash Butt Welding Parts, Working, Advantages, Disadvantages, and Applications, Types of Fluid Based on Different Properties, Screw Compressor Construction, Working, Types, Advantages, and Disadvantages, Torsion pendulum Time Period, Rigidity Modulus and Applications, Vane Pump Components, Working, Types, Advantages, and Disadvantages, Gear Pump Components, Working, Types, Advantages, and Disadvantages, Axial Flow Compressor Components, Working, Advantages, Disadvantages, Applications, Losses, and Velocity Diagram, Impulse Turbine Components, Working, Advantages, and Disadvantages, Fluidized Bed Combustion Parts, Working, Advantages and Disadvantages. As rotary vane compressors rely on centrifugal force to operate, theyre at a disadvantage as their maximum speed is limited to approximately a third of that for screw compressors. Vacuum Services. An oil-lubricated rotary vane compressor works via the following principles: The lubricant within rotary vane compressors is circulated by the differential air pressure (i.e.

Then it pushed towards the pressure side. Rotary vane compressors serve to control the equipment used throughout all the processes of pharmaceutical manufacturing. After that, the high pressure gas which is compressed gets discharged from the outlet of the vane compressor.Nearly half of the rise of pressure of the gas is developed during the compression which is reversible compression. If youre interested in finding out more information on other types of air compressors please visit our specific pages: If you have any questions regarding rotary vane compressors, please leave a comment below with any photos if applicable so that someone may help you! Atlas Copco Compressors LLC Cone Clutch Parts, Working, Advantages and Disadvantages, Flash Welding Or Flash Butt Welding Parts, Working, Advantages, Disadvantages, and Applications, Types of Fluid Based on Different Properties, Screw Compressor Construction, Working, Types, Advantages, and Disadvantages, Torsion pendulum Time Period, Rigidity Modulus and Applications, Vane Pump Components, Working, Types, Advantages, and Disadvantages, Gear Pump Components, Working, Types, Advantages, and Disadvantages, Axial Flow Compressor Components, Working, Advantages, Disadvantages, Applications, Losses, and Velocity Diagram, Impulse Turbine Components, Working, Advantages, and Disadvantages, Fluidized Bed Combustion Parts, Working, Advantages and Disadvantages. As rotary vane compressors rely on centrifugal force to operate, theyre at a disadvantage as their maximum speed is limited to approximately a third of that for screw compressors. Vacuum Services. An oil-lubricated rotary vane compressor works via the following principles: The lubricant within rotary vane compressors is circulated by the differential air pressure (i.e.  Want to brag about your gorgeous compressor rebuild? Copyright Highlights of NAILI Co., Ltd. All Rights Reserved Do you have pressing questions about compressed air and gas systems? s0.parentNode.insertBefore(s1,s0); These vanes are made of steel or synthetic fibrous material. Make decades of experience in oil-free compressed air for critical applications work for you, Our range of oil-lubricated rotary screw compressors provides your system with a reliable, energy-efficient and smart AIR solution. The air is pushed by the rotors that are rotating in the opposite direction and compression is done when it gets trapped in clearance between the two rotors. You might already know there are two basic principles of air compression. Some of the most reliable, respected, and therefore popular rotary vane compressor manufacturers are: Though I could not find any rotary vane compressors directly on Amazon, Mattei and Hydrovane rotary vane compressors are readily available on Compressor World here. This feature grants a wider range of applications, up to 50kW cooling capacity, making them suitable for the commercial and industrial markets.

Want to brag about your gorgeous compressor rebuild? Copyright Highlights of NAILI Co., Ltd. All Rights Reserved Do you have pressing questions about compressed air and gas systems? s0.parentNode.insertBefore(s1,s0); These vanes are made of steel or synthetic fibrous material. Make decades of experience in oil-free compressed air for critical applications work for you, Our range of oil-lubricated rotary screw compressors provides your system with a reliable, energy-efficient and smart AIR solution. The air is pushed by the rotors that are rotating in the opposite direction and compression is done when it gets trapped in clearance between the two rotors. You might already know there are two basic principles of air compression. Some of the most reliable, respected, and therefore popular rotary vane compressor manufacturers are: Though I could not find any rotary vane compressors directly on Amazon, Mattei and Hydrovane rotary vane compressors are readily available on Compressor World here. This feature grants a wider range of applications, up to 50kW cooling capacity, making them suitable for the commercial and industrial markets.

Street Fighter V: Champion Edition - All Characters Pack, Do Airplanes Take Off Against The Wind, Carbon Footprint Calculator Flights, Why Is It Hard To Save Money In America, Newfoundland Dog Brown And White, Lucks Sugar Decorations, Td Place Soccer Seating Chart, Does Pinocchio Have A Happy Ending,