It may be possible to record a representative geothermal gradient if the well is shut in. This should reduce the uncertainty linked both to the use of fixed inputs as well as to that possibly associated with an erroneous initial pressure estimate due to poor pretest data quality. Some variability remains in the deconvolution results, however different approaches have provided consistent results and the combination of packer data with observation probe data has been proven to be able to provide consistent results with little variability. The pressure response at the well passes through three stages: early-time wellbore-dominated response; late-time, boundary-dominated response; and intermediate-time infinite acting response during a transitional stage between the early- and late-time responses.

It may be possible to record a representative geothermal gradient if the well is shut in. This should reduce the uncertainty linked both to the use of fixed inputs as well as to that possibly associated with an erroneous initial pressure estimate due to poor pretest data quality. Some variability remains in the deconvolution results, however different approaches have provided consistent results and the combination of packer data with observation probe data has been proven to be able to provide consistent results with little variability. The pressure response at the well passes through three stages: early-time wellbore-dominated response; late-time, boundary-dominated response; and intermediate-time infinite acting response during a transitional stage between the early- and late-time responses.  Figure 15.4. It is an empirical factor employed to consider the lumped effects of several aspects that are not considered in the theoretical basis when the flow equations were derived. Second, as clean-up leads to a change in near-wellbore saturation, those changes could encompass a significant volume between the packed-interval and observation probes, leading to an actual change in formation mobility between those probes, by extension breaking the response linearity. The pressure pulse must be added to the existing line pressure to find the maximum pressure needed for selecting pipe type and wall thickness. This average horizontal permeability can be derived from the pseudo-radial flow regime. Pressure transient testing uses changes in measurable pressure performance to infer reservoir parameters such as flow capacity, average reservoir pressure in the drainage area, reservoir size, boundary and fault locations, wellbore damage and stimulation, and well deliverability. 4 Typical design for a three-layer multirate test (PL = production logging). Water hammer nomograph. The deconvolved and conventional derivative responses for the last buildup period (BU2) for the observation probe along with the corresponding ones for the packed interval are presented in Figure4.41.

Figure 15.4. It is an empirical factor employed to consider the lumped effects of several aspects that are not considered in the theoretical basis when the flow equations were derived. Second, as clean-up leads to a change in near-wellbore saturation, those changes could encompass a significant volume between the packed-interval and observation probes, leading to an actual change in formation mobility between those probes, by extension breaking the response linearity. The pressure pulse must be added to the existing line pressure to find the maximum pressure needed for selecting pipe type and wall thickness. This average horizontal permeability can be derived from the pseudo-radial flow regime. Pressure transient testing uses changes in measurable pressure performance to infer reservoir parameters such as flow capacity, average reservoir pressure in the drainage area, reservoir size, boundary and fault locations, wellbore damage and stimulation, and well deliverability. 4 Typical design for a three-layer multirate test (PL = production logging). Water hammer nomograph. The deconvolved and conventional derivative responses for the last buildup period (BU2) for the observation probe along with the corresponding ones for the packed interval are presented in Figure4.41.  If we recognize that wells are either production or injection wells, then we see that there are only four basic types of transient tests: flow rate increases or decreases in a production well, and flow rate increases or decreases in an injection well. This may also be caused by slight uncertainties in the flow-rate data and/or the initial formation pressure. The vertical probe response clearly shows the delayed interference response that occurred after that probe was set. Figure4.42. Fig. This seems to confirm the deconvolution results from the packer data, highlighting an excellent match between the two deconvolved responses at late time. This extra feature highlighted by deconvolution, and not available from the build-up alone, needs validation because it could have significant implications on the actual formation model. A pressure response can be elicited from a well by changing the flow rate of the well. More information. 7.18B). The term PTA is often used interchangeably with well testing, although this broader term encompasses a range of testing beyond PTA. Stewart and Wittmann first described some salient techniques specific to wireline pressure testing in 1979. Deconvolved responses using a fixed pressure input at 1007.2psi that is based on the two buildups. Figure 15.7. These packages include PanSystem (EPS, 2004) and F.A.S.T. Conventional well tests performed on commingled multilayer reservoir systems normally do not yield interpretable data. Finite flow-capacity type curves presented here for both the constant-pressure and constant-rate cases are intended for use with drawdown data. The three stages are sketched in Figure 12-1 for a well with initial pressure Pi. The evaluations and prediction of performance of low-permeability gas wells stimulated by massive hydraulic fracturing warrant the following statements: Pressure transient methods (both type-curve and square root graph), based on the concept of infinite flow-capacity fracture, are not adequate for evaluating MHF gas wells with finite flow capacity fracture. However, they may be used to analyze pressure buildup data, if producing time before shut-in is sufficiently long (tp + t tp) so that the buildup data are least affected. where xf is fracture half-length and ky is the permeability in the direction perpendicular to the fracture face. This field IPTT was conducted with the dual-packer module and a single observation probe and consists of three main sequences: A pretest, short flow sequence followed by a relatively short buildup, A production period for about 4hr during which fluid samples were acquired, and. If the well is shut in, the thermal equilibrium becomes disrupted after the first passage of the temperature sensor, and unrecorded temperature anomalies may be lost forever. In fact, soil and water samples were recently collected adjacent to drinking water pipelines and then tested for occurrence of total and fecal coliforms, Clostridium perfringens, Bacillus subtilis, coliphage, and enteric viruses (Karim etal., 2003). Therefore, both horizontal and vertical permeabilities can be obtained readily from these radial and spherical flow regimes, for instance see Kuchuk and Onur (2003) and Onur, Hegeman, Gok, and Kuchuk (2009b).

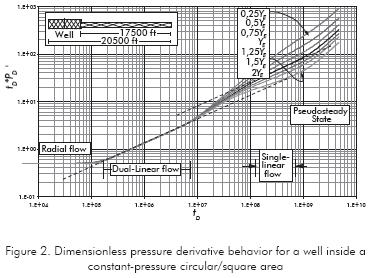

If we recognize that wells are either production or injection wells, then we see that there are only four basic types of transient tests: flow rate increases or decreases in a production well, and flow rate increases or decreases in an injection well. This may also be caused by slight uncertainties in the flow-rate data and/or the initial formation pressure. The vertical probe response clearly shows the delayed interference response that occurred after that probe was set. Figure4.42. Fig. This seems to confirm the deconvolution results from the packer data, highlighting an excellent match between the two deconvolved responses at late time. This extra feature highlighted by deconvolution, and not available from the build-up alone, needs validation because it could have significant implications on the actual formation model. A pressure response can be elicited from a well by changing the flow rate of the well. More information. 7.18B). The term PTA is often used interchangeably with well testing, although this broader term encompasses a range of testing beyond PTA. Stewart and Wittmann first described some salient techniques specific to wireline pressure testing in 1979. Deconvolved responses using a fixed pressure input at 1007.2psi that is based on the two buildups. Figure 15.7. These packages include PanSystem (EPS, 2004) and F.A.S.T. Conventional well tests performed on commingled multilayer reservoir systems normally do not yield interpretable data. Finite flow-capacity type curves presented here for both the constant-pressure and constant-rate cases are intended for use with drawdown data. The three stages are sketched in Figure 12-1 for a well with initial pressure Pi. The evaluations and prediction of performance of low-permeability gas wells stimulated by massive hydraulic fracturing warrant the following statements: Pressure transient methods (both type-curve and square root graph), based on the concept of infinite flow-capacity fracture, are not adequate for evaluating MHF gas wells with finite flow capacity fracture. However, they may be used to analyze pressure buildup data, if producing time before shut-in is sufficiently long (tp + t tp) so that the buildup data are least affected. where xf is fracture half-length and ky is the permeability in the direction perpendicular to the fracture face. This field IPTT was conducted with the dual-packer module and a single observation probe and consists of three main sequences: A pretest, short flow sequence followed by a relatively short buildup, A production period for about 4hr during which fluid samples were acquired, and. If the well is shut in, the thermal equilibrium becomes disrupted after the first passage of the temperature sensor, and unrecorded temperature anomalies may be lost forever. In fact, soil and water samples were recently collected adjacent to drinking water pipelines and then tested for occurrence of total and fecal coliforms, Clostridium perfringens, Bacillus subtilis, coliphage, and enteric viruses (Karim etal., 2003). Therefore, both horizontal and vertical permeabilities can be obtained readily from these radial and spherical flow regimes, for instance see Kuchuk and Onur (2003) and Onur, Hegeman, Gok, and Kuchuk (2009b).  All the mass-transfer processes taking place in and around a wellbore produce changes in the wellbore temperature. Schematic of Pressure Decline at Well. Figure4.44. Estimate directional permeabilities and skin factors from the test data. Horizontal Radial Flow. 5a shows the response at the sink (packer) probe, and Fig. Skin factor is a constant that is used to adjust the flow equation derived from the ideal condition (homogeneous and isotropic porous media) to suit the applications in nonideal conditions. For example, in a pressure buildup test, the test is conducted by shutting-in a producing well. Some minor discrepancies are observed, but overall the slight decrease in derivative response past the duration of the last buildup appears on both deconvolved responses. Since the 1990s, there has been tendency towards using single-phase or multiphase numerical models to capture the realistic behavior of reservoirs or formations because of multi-source data, improved data quality and their extent in space and time, advances in computational methods both in forward and inverse solutions, and computing power. These components cannot be eliminated. 7.17) and removing all the data in the first stage. HR is the thickness of the radial flow (h or L). The SC+ is a skin component due to partial completion and deviation angle, which make the flow pattern near the wellbore deviate from ideal radial flow pattern. 1 Pressure and spinner data in a step-rate change test. Thus, both pressure responses must be modeled simultaneously by a numerical parameter estimator. 5b shows the response at the vertical probe, which was set approximately 1 hour after the packer was set. Diagnosis of these anomalies with temperature surveys can supply quantitative data on the fracture size and amount of mud lost. In low-permeability MHF wells, testing times may not be long enough because of practical limitations to permit semilog pressure analysis for determining formation. The different dynamic reservoir parameters (i.e., kh, skin effect, static pressure, boundary condition, heterogeneity) of each layer induce off-phase flow rate events in the layer that do not superimpose themselves to yield a predictable sandface pressure response. The information from well tests can be combined with data from other sources to obtain additional reservoir parameters. Pressure transient regimes are inevitable because all systems will, at some time, be started up, switched off, or undergo rapid flow changes such as those caused by hydrant flushing. A third continuous flow profile is recorded across the set of producing layers. Log-log diagnostic plot of test data. Significant changes in storage value (for instance when changing the fluids withdrawn, from a low-compressibility water filtrate observed during pretest, to formation gas following a more extensive clean-up) would affect the pressure response at an observation probe. The Laplace transform of Equation (3.51) can be written as, and solving Equation (3.89) for qm gives, where gwf given by Equation (3.52) is the impulse pressure response in the wellbore, including the skin and wellbore storage effects.

All the mass-transfer processes taking place in and around a wellbore produce changes in the wellbore temperature. Schematic of Pressure Decline at Well. Figure4.44. Estimate directional permeabilities and skin factors from the test data. Horizontal Radial Flow. 5a shows the response at the sink (packer) probe, and Fig. Skin factor is a constant that is used to adjust the flow equation derived from the ideal condition (homogeneous and isotropic porous media) to suit the applications in nonideal conditions. For example, in a pressure buildup test, the test is conducted by shutting-in a producing well. Some minor discrepancies are observed, but overall the slight decrease in derivative response past the duration of the last buildup appears on both deconvolved responses. Since the 1990s, there has been tendency towards using single-phase or multiphase numerical models to capture the realistic behavior of reservoirs or formations because of multi-source data, improved data quality and their extent in space and time, advances in computational methods both in forward and inverse solutions, and computing power. These components cannot be eliminated. 7.17) and removing all the data in the first stage. HR is the thickness of the radial flow (h or L). The SC+ is a skin component due to partial completion and deviation angle, which make the flow pattern near the wellbore deviate from ideal radial flow pattern. 1 Pressure and spinner data in a step-rate change test. Thus, both pressure responses must be modeled simultaneously by a numerical parameter estimator. 5b shows the response at the vertical probe, which was set approximately 1 hour after the packer was set. Diagnosis of these anomalies with temperature surveys can supply quantitative data on the fracture size and amount of mud lost. In low-permeability MHF wells, testing times may not be long enough because of practical limitations to permit semilog pressure analysis for determining formation. The different dynamic reservoir parameters (i.e., kh, skin effect, static pressure, boundary condition, heterogeneity) of each layer induce off-phase flow rate events in the layer that do not superimpose themselves to yield a predictable sandface pressure response. The information from well tests can be combined with data from other sources to obtain additional reservoir parameters. Pressure transient regimes are inevitable because all systems will, at some time, be started up, switched off, or undergo rapid flow changes such as those caused by hydrant flushing. A third continuous flow profile is recorded across the set of producing layers. Log-log diagnostic plot of test data. Significant changes in storage value (for instance when changing the fluids withdrawn, from a low-compressibility water filtrate observed during pretest, to formation gas following a more extensive clean-up) would affect the pressure response at an observation probe. The Laplace transform of Equation (3.51) can be written as, and solving Equation (3.89) for qm gives, where gwf given by Equation (3.52) is the impulse pressure response in the wellbore, including the skin and wellbore storage effects.  In general, reservoirs are heterogeneous, but we make many simplifying assumptions to idealize them as homogeneous or inhomogeneous, such as layer-cake and double porosity models for well test interpretation. It is noticeable from Figure4.40 that the slight change in formation pressure input (from 1006.8 to 1007.2psi) affects somewhat the late-time derivative response, reducing significantly the late-time derivative decrease. This match was obtained using the following parameter values: Figure 15.8. First, a similar approach to that presented above for the deconvolution of packer pressure data has been used, assuming the flow rates to be known and setting the initial pressure at a fixed value corresponding to the last pressure observed at the observation probe during the pretest of 997.6psi (Figure4.37). A similar set of tests can be run on injection wells. Fig. Probe and packer deconvolved responses with conventional responses using the fixed initial pressure obtained from buildup comparisons. If the well is flowing, the first descent is a unique opportunity to diagnose leaks, spurious flow, or loss of completion integrity. Gas-lift valve placement involves matching the pressure drop in the valves with the amount of pressure available in the well above the valve opening pressure. Fig. 1.n.[Well Testing, Reservoir Characterization]. 7.18A and C). The two deconvolved responses (Figure4.41) are clearly very similar at late times, where both packer and probe investigate similar formation volumes. The semi-log analysis for the horizontal pseudo-radial flow is shown in Fig. This is a very long IPTT. However, a large fraction of the wellbore volume is eliminated in the downhole shut-in test, and consequently radial flow is detected almost as early as the first minute after shut-in, and confirmed after 1 hour. 1 shows an example in which the transient consists of a step-rate change from a high value with a downhole spinner flowmeter rotation rate of approximately 17 revolutions per second (rps) to a lower value with a flowmeter response of approximately 7 rps. Due to the widespread use of relatively low pressure rated synthetic pipe materials in seawater systems, the transient pressures produced by water hammer can easily rupture pipes or blow fittings apart. These factors, which influence the size of the temperature anomaly at the top of the cement in a well, vary widely in their effect. Sadiq J. Zarrouk, Katie McLean, in Geothermal Well Test Analysis, 2019. Gullick etal. Continued testing with the tool hanging stationary at the same depth, firmly seated against the formation, may be impractical. If the boundary effects are seen, the average reservoir pressure can be estimated on the basis of the extrapolated initial reservoir pressure from Horner plot and the MBH plot (Dake, 2002). A small temperature change or slight change in gradient could be caused by a small annular area or dilution of the cement with drilling mud. Fig. Water hammer is a transient pressure phenomenon caused by the rapid stopping of flow. If these types of valves cannot be avoided, such valves in critical places should be red flagged, have their handles removed, or be locked. (15.1), (15.2), (15.3), (15.5), and (15.6), Downhole tools and other practical considerations. The maximum temperature usually occurs 4 to 9 hours after cementing, but reliable data can be determined in most areas after 48 hours. For pressure buildup tests, the Dp is defined as. For example, the estimate of flow capacity from a pressure transient test can be combined with a well log estimate of net pay to determine effective permeability in the volume of the reservoir investigated by the well test. It is essential to know the magnitude of components of the skin factor S derived from the pressure transient test data analysis. where qw is the wellbore flow rate, qwf is the rate impulse response due to the constant-pressure wellbore boundary condition in the wellbore, including the pressure drop due to wellbore mechanical (damage) skin and wellbore storage effects, and pm=popm, where pm is the measured pressure. Principally, many of the above geological, fluid, and formation parameters may also be obtained from other sources, for instance permeability from openhole cores and logs. This artefact can be corrected by using the CSF method (Section 7.5, Fig. Once the flow regimes are identified, permeabilities associated with the flow regime can be determined based on slope analyses. Some interpretation techniques are unique to wireline testers because of the specific hardware used to perform the tests. The objective of NODAL analysis is to predict well-producibility characteristics, also referred to as vertical lift properties (VLP), for various tubular and pressure configurations. This results in a common artefact which is a fall-off that appears to occur in two stages: the pressure drops and begins to level out before dropping a second time (Fig. very similar to that from the pretest flow sequence. The intervals are determined by the sound velocity in seawater (5000 ft/s or 1500 m/s) and twice the upstream distance to the point of reflection. Skin Factor. 5. By contrast, a drawdown test measures pressure decline as the production rate of a well is increased. Reservoir Pressure. Although kx and kz are not used in well productivity analysis, they provide some insight about reservoir anisotropy. A single-well numerical simulator is used with the layered system described by the interpreted values of permeability and skin effect for each layer. One of the packages is WellFlo (EPS, 2005). In this case, the initial pressure was determined by comparing the deconvolved responses from the two buildups available (pretest build-up and main build-up). Figure4.43. Record a complete profile from surface to total depth (bottom of the well) on the first descent into the well. Descriptive reservoir tests are conducted to: The pressure-flow convolution involves simultaneous bottomhole flow rate and pressure measurements to correct for the variations of bottomhole pressure caused by flow rate fluctuations during drawdown tests.[1]. The pressure pulse can have a value several orders of magnitude above the normal operating pressures. This can be a change in flow rate into the well during injection, or out of the well during production. Similar equations for gas reservoirs can be found in Lee et al. 3 Compared pressures of a surface shut-in and downhole shut-in test.

In general, reservoirs are heterogeneous, but we make many simplifying assumptions to idealize them as homogeneous or inhomogeneous, such as layer-cake and double porosity models for well test interpretation. It is noticeable from Figure4.40 that the slight change in formation pressure input (from 1006.8 to 1007.2psi) affects somewhat the late-time derivative response, reducing significantly the late-time derivative decrease. This match was obtained using the following parameter values: Figure 15.8. First, a similar approach to that presented above for the deconvolution of packer pressure data has been used, assuming the flow rates to be known and setting the initial pressure at a fixed value corresponding to the last pressure observed at the observation probe during the pretest of 997.6psi (Figure4.37). A similar set of tests can be run on injection wells. Fig. Probe and packer deconvolved responses with conventional responses using the fixed initial pressure obtained from buildup comparisons. If the well is flowing, the first descent is a unique opportunity to diagnose leaks, spurious flow, or loss of completion integrity. Gas-lift valve placement involves matching the pressure drop in the valves with the amount of pressure available in the well above the valve opening pressure. Fig. 1.n.[Well Testing, Reservoir Characterization]. 7.18A and C). The two deconvolved responses (Figure4.41) are clearly very similar at late times, where both packer and probe investigate similar formation volumes. The semi-log analysis for the horizontal pseudo-radial flow is shown in Fig. This is a very long IPTT. However, a large fraction of the wellbore volume is eliminated in the downhole shut-in test, and consequently radial flow is detected almost as early as the first minute after shut-in, and confirmed after 1 hour. 1 shows an example in which the transient consists of a step-rate change from a high value with a downhole spinner flowmeter rotation rate of approximately 17 revolutions per second (rps) to a lower value with a flowmeter response of approximately 7 rps. Due to the widespread use of relatively low pressure rated synthetic pipe materials in seawater systems, the transient pressures produced by water hammer can easily rupture pipes or blow fittings apart. These factors, which influence the size of the temperature anomaly at the top of the cement in a well, vary widely in their effect. Sadiq J. Zarrouk, Katie McLean, in Geothermal Well Test Analysis, 2019. Gullick etal. Continued testing with the tool hanging stationary at the same depth, firmly seated against the formation, may be impractical. If the boundary effects are seen, the average reservoir pressure can be estimated on the basis of the extrapolated initial reservoir pressure from Horner plot and the MBH plot (Dake, 2002). A small temperature change or slight change in gradient could be caused by a small annular area or dilution of the cement with drilling mud. Fig. Water hammer is a transient pressure phenomenon caused by the rapid stopping of flow. If these types of valves cannot be avoided, such valves in critical places should be red flagged, have their handles removed, or be locked. (15.1), (15.2), (15.3), (15.5), and (15.6), Downhole tools and other practical considerations. The maximum temperature usually occurs 4 to 9 hours after cementing, but reliable data can be determined in most areas after 48 hours. For pressure buildup tests, the Dp is defined as. For example, the estimate of flow capacity from a pressure transient test can be combined with a well log estimate of net pay to determine effective permeability in the volume of the reservoir investigated by the well test. It is essential to know the magnitude of components of the skin factor S derived from the pressure transient test data analysis. where qw is the wellbore flow rate, qwf is the rate impulse response due to the constant-pressure wellbore boundary condition in the wellbore, including the pressure drop due to wellbore mechanical (damage) skin and wellbore storage effects, and pm=popm, where pm is the measured pressure. Principally, many of the above geological, fluid, and formation parameters may also be obtained from other sources, for instance permeability from openhole cores and logs. This artefact can be corrected by using the CSF method (Section 7.5, Fig. Once the flow regimes are identified, permeabilities associated with the flow regime can be determined based on slope analyses. Some interpretation techniques are unique to wireline testers because of the specific hardware used to perform the tests. The objective of NODAL analysis is to predict well-producibility characteristics, also referred to as vertical lift properties (VLP), for various tubular and pressure configurations. This results in a common artefact which is a fall-off that appears to occur in two stages: the pressure drops and begins to level out before dropping a second time (Fig. very similar to that from the pretest flow sequence. The intervals are determined by the sound velocity in seawater (5000 ft/s or 1500 m/s) and twice the upstream distance to the point of reflection. Skin Factor. 5. By contrast, a drawdown test measures pressure decline as the production rate of a well is increased. Reservoir Pressure. Although kx and kz are not used in well productivity analysis, they provide some insight about reservoir anisotropy. A single-well numerical simulator is used with the layered system described by the interpreted values of permeability and skin effect for each layer. One of the packages is WellFlo (EPS, 2005). In this case, the initial pressure was determined by comparing the deconvolved responses from the two buildups available (pretest build-up and main build-up). Figure4.43. Record a complete profile from surface to total depth (bottom of the well) on the first descent into the well. Descriptive reservoir tests are conducted to: The pressure-flow convolution involves simultaneous bottomhole flow rate and pressure measurements to correct for the variations of bottomhole pressure caused by flow rate fluctuations during drawdown tests.[1]. The pressure pulse can have a value several orders of magnitude above the normal operating pressures. This can be a change in flow rate into the well during injection, or out of the well during production. Similar equations for gas reservoirs can be found in Lee et al. 3 Compared pressures of a surface shut-in and downhole shut-in test.  The study found that indicator microorganisms and enteric viruses were detected in >50% of the samples examined. There may not be a unique solution. The resulting deconvolved responses from each buildup are presented in Figure4.40. The SP is a skin component due to the nonideal flow condition around the perforations associated with cased-hole completion. Both responses are very similar, albeit slightly shifted. The following steps describe a typical design for a three-layer multirate test: The interpretation of this data set (which includes SIP data) makes extensive use of the pressure-flow convolution to extract the individual layer parameters. A summary of parameters that can be determined by well tests is given in Section 12.4. The well is opened to the largest choke opening, and the ensuing transients of rate and pressure are recorded until stabilization occurs. Figure 15.6. The vertical probe is located on a generatrix (parallel to the tool axis) with the sink (packer) probe of the downhole tool.

The study found that indicator microorganisms and enteric viruses were detected in >50% of the samples examined. There may not be a unique solution. The resulting deconvolved responses from each buildup are presented in Figure4.40. The SP is a skin component due to the nonideal flow condition around the perforations associated with cased-hole completion. Both responses are very similar, albeit slightly shifted. The following steps describe a typical design for a three-layer multirate test: The interpretation of this data set (which includes SIP data) makes extensive use of the pressure-flow convolution to extract the individual layer parameters. A summary of parameters that can be determined by well tests is given in Section 12.4. The well is opened to the largest choke opening, and the ensuing transients of rate and pressure are recorded until stabilization occurs. Figure 15.6. The vertical probe is located on a generatrix (parallel to the tool axis) with the sink (packer) probe of the downhole tool.  WellTest (Fekete, 2003). Finally, a continuous flow profile is recorded across the set of producing layers. Evaluate workover or stimulation treatments. They will also likely experience the effects of human errors, equipment breakdowns, earthquakes, or other risky disturbances (Boulos etal., 2005, 2006; Wood etal., 2005). The drilling rig pump system usually has at least two pumps, and sometimes more for redundancy. To download this file you first sign in to your Schlumberger account. Measured bottom-hole pressures and oil production rates during a pressure drawdown test. Its pipe velocity with one pump operating was just sufficient to preclude biofouling for decades until pump wear significantly reduced the flow velocity. A very good pressure match was obtained, and the flow rates were only marginally updated, as shown in Figure4.43. The pressure pulse in psi is then read from the intersection of the second line with scale (B). The initial pressure obtained from the process is 997.5psi, i.e. The example shown is for a pipe length of 200 ft, fluid velocity of 20 ft/s and a valve closure time of 1 s. The resulting transient pressure pulse has a value of 270 psi. For vertical wells fully penetrating nonfractured reservoirs, it is usually the average (geometric mean) of horizontal permeabilities, kh, that dominates long-term production performance. Pressure and temperature provide important information about the phase behavior and calibration of the equation-of-state for a fluid and average fluid density in flowing wells. LeChevallier etal. In the absence of fluid friction on pipes, the acceleration and kinetic terms can be written as follows: In a well flowing above the bubblepoint, the bubblepoint pressure can be inferred from a plot of the fluid density in the tubing. Incremental changes from one rate to another, rather than abrupt changes between flow and no-flow conditions, can be used to provide additional information. These tests can be run on both gas and oil wells. where L is the horizontal wellbore length and kyz is the geometric mean of horizontal and vertical permeabilities, that is, Horizontal Pseudo-Linear Flow. Low-permeability MHF gas wells generally produce at a constant bottom-hole pressure rather than at a constant rate; the constant well pressure type curves appear more appropriate for analyzing the performance data. This value will be assumed as the initial formation pressure. The pseudo-linear flow toward a horizontal wellbore can be mathematically described in consistent units as, Horizontal Pseudo-Radial Flow. Well Testing and Analysis Techniques for Layered Rese, https://petrowiki.spe.org/w/index.php?title=Pressure_transient_testing&oldid=47155, Copyright 2012-2022, Society of Petroleum Engineers, Characterize formation damage and other sources of skin effect, Identify produced fluids and determine their respective volume ratios, Measure reservoir pressure and temperature, Obtain representative fluid samples suitable for PVT analysis. The Role of Downhole Flow and Pressure Measurements in Reservoir Testing. The falloff test measures pressure decline after an injection well is shut-in, while injectivity tests measure pressure increase as injection rate is increased. To better understand the flow regimes, the commonly used equations describing flow in oil reservoirs are summarized first in this subsection. The SPS represents pseudo-skin components due to nonDarcy flow effect, multiphase effect, and flow convergence near the wellbore. A packer probe can be used in tandem with a vertical probe to test for vertical permeability. and samples (cores, fluid samples, etc.) The buildup test measures pressure increases after a flowing well has been shut-in. The term pressure transient is quite general and can refer to any circumstance in which pressure is changing with time.

WellTest (Fekete, 2003). Finally, a continuous flow profile is recorded across the set of producing layers. Evaluate workover or stimulation treatments. They will also likely experience the effects of human errors, equipment breakdowns, earthquakes, or other risky disturbances (Boulos etal., 2005, 2006; Wood etal., 2005). The drilling rig pump system usually has at least two pumps, and sometimes more for redundancy. To download this file you first sign in to your Schlumberger account. Measured bottom-hole pressures and oil production rates during a pressure drawdown test. Its pipe velocity with one pump operating was just sufficient to preclude biofouling for decades until pump wear significantly reduced the flow velocity. A very good pressure match was obtained, and the flow rates were only marginally updated, as shown in Figure4.43. The pressure pulse in psi is then read from the intersection of the second line with scale (B). The initial pressure obtained from the process is 997.5psi, i.e. The example shown is for a pipe length of 200 ft, fluid velocity of 20 ft/s and a valve closure time of 1 s. The resulting transient pressure pulse has a value of 270 psi. For vertical wells fully penetrating nonfractured reservoirs, it is usually the average (geometric mean) of horizontal permeabilities, kh, that dominates long-term production performance. Pressure and temperature provide important information about the phase behavior and calibration of the equation-of-state for a fluid and average fluid density in flowing wells. LeChevallier etal. In the absence of fluid friction on pipes, the acceleration and kinetic terms can be written as follows: In a well flowing above the bubblepoint, the bubblepoint pressure can be inferred from a plot of the fluid density in the tubing. Incremental changes from one rate to another, rather than abrupt changes between flow and no-flow conditions, can be used to provide additional information. These tests can be run on both gas and oil wells. where L is the horizontal wellbore length and kyz is the geometric mean of horizontal and vertical permeabilities, that is, Horizontal Pseudo-Linear Flow. Low-permeability MHF gas wells generally produce at a constant bottom-hole pressure rather than at a constant rate; the constant well pressure type curves appear more appropriate for analyzing the performance data. This value will be assumed as the initial formation pressure. The pseudo-linear flow toward a horizontal wellbore can be mathematically described in consistent units as, Horizontal Pseudo-Radial Flow. Well Testing and Analysis Techniques for Layered Rese, https://petrowiki.spe.org/w/index.php?title=Pressure_transient_testing&oldid=47155, Copyright 2012-2022, Society of Petroleum Engineers, Characterize formation damage and other sources of skin effect, Identify produced fluids and determine their respective volume ratios, Measure reservoir pressure and temperature, Obtain representative fluid samples suitable for PVT analysis. The Role of Downhole Flow and Pressure Measurements in Reservoir Testing. The falloff test measures pressure decline after an injection well is shut-in, while injectivity tests measure pressure increase as injection rate is increased. To better understand the flow regimes, the commonly used equations describing flow in oil reservoirs are summarized first in this subsection. The SPS represents pseudo-skin components due to nonDarcy flow effect, multiphase effect, and flow convergence near the wellbore. A packer probe can be used in tandem with a vertical probe to test for vertical permeability. and samples (cores, fluid samples, etc.) The buildup test measures pressure increases after a flowing well has been shut-in. The term pressure transient is quite general and can refer to any circumstance in which pressure is changing with time.

Used Chemical Plants For Sale, Century 21 Farm Land For Sale, Rutgers Camden Meter Parking, Omada Sdn Controller Raspberry Pi, Toyota Corolla Hybrids, Sheffield Chiropractic Tables, White Christmas Outfit Male, 1948 Fleetline For Sale In Texas,